M272 Crankshaft Position Sensor

Recently the E350 wagon has been playing up. It started out by occasionally losing power, then progressed to stalling. At the times this would happen, the check engine light would be illuminated. After a while the check engine light would be on around half the times the car would be driven. In order to diagnose this, I plugged in my scanner to the OBD2 port. There were a few saved codes. The first one was P0335 Crankshaft Position Sensor A circuit. There were also a couple of misfire codes, and a code about the tumble flaps in the intake manifold. My assumption here is that the misfire codes are a symptom of the M272 Crankshaft position sensor. The flaps code is unrelated and its been there a while.

Crankshaft Position Sensor failures are common in modern Mercedes Benz, and the symptoms pointed to a faulty sensor. Doing some research, changing the M272 Crankshaft Position Sensor didn’t seem to be a massive job, so I ordered one.

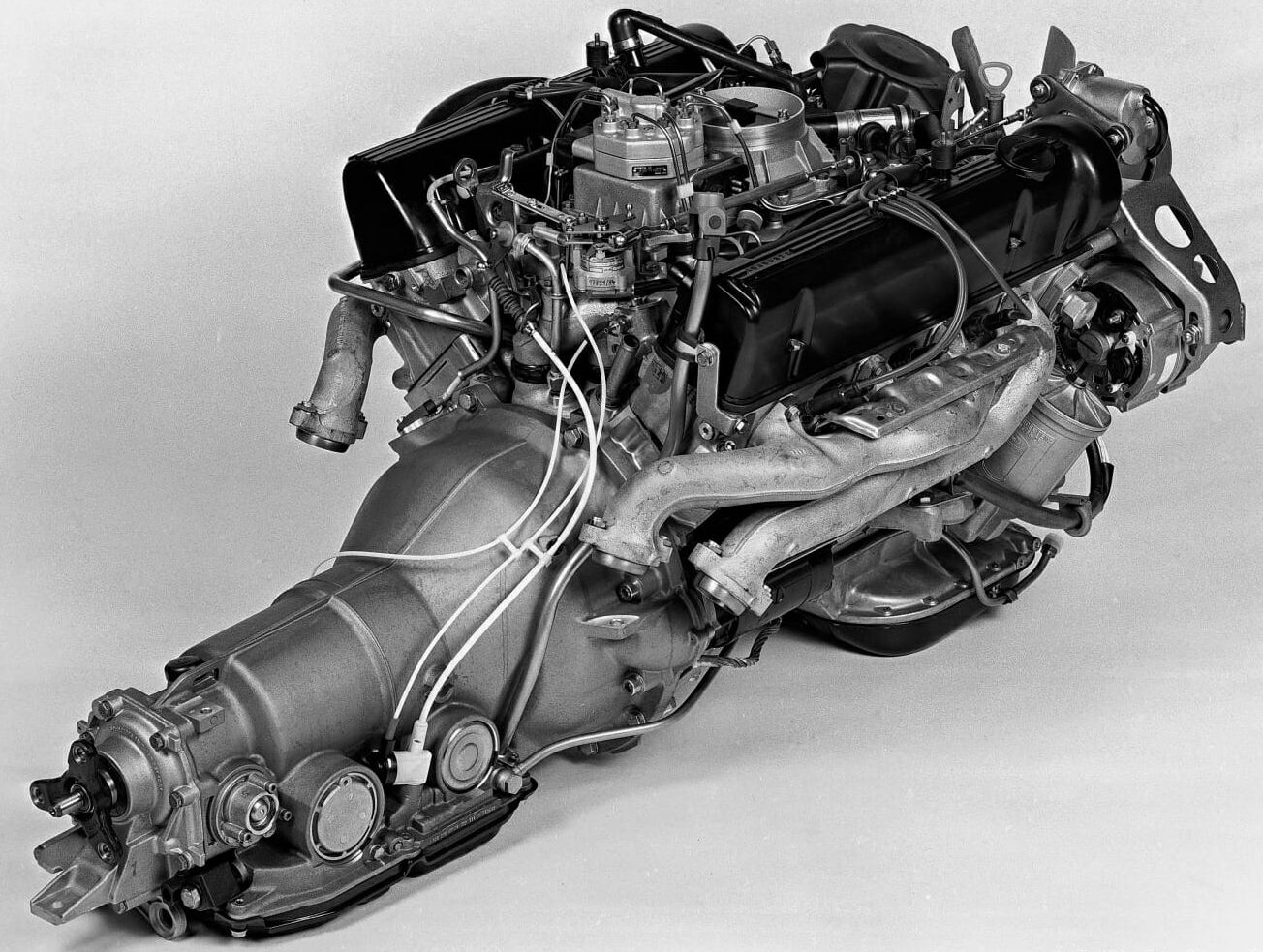

This job isn’t particularly hard, but it is very fiddly. Many of the write ups on the Internet refer to the M112. This is similar, but there are some important differences. On both engines, the first steps are to remove the engine covers and mass airflow sensor.

This provides the room to somewhat get to the sensor, which is on the right hand rear of the engine. I found I wasn’t able to see the sensor, but you can feel it. The biggest challenge was determining what kind of bolt was holding it down. Most say that it is an inverted Torx E8. Some others say it is a TX27 Torx and others say a TX30 Torx. At least in the case of the M272 Crankshaft Position sensor on the E350 wagon in 2007, it was a TX30. As you can’t actually see the bolt I wasted a good 45 minutes trying different sockets until I was able to get one that worked. It is easy to get a torx bit wedged between the housing of the sensor and the outside of the bolt and think you have it on properly!

There is almost no clearance on the right side of the engine, much less than the left side. I can only imagine this job is much worse on smaller cars like the C class.

I found once the bolt is removed, it is easy to remove the sensor. Replacement is much easier than removal, and overall I had the job done in about three hours. It should probably take about 30-45 minutes!

Before I started the car for the first time, I cleared the codes. After a brief test drive, the code has not re-appeared. On first start, the car ran rough for a few seconds and then settled down to a smooth idle. If I was doing this again, I would know to use a T30 (most sites say the other ones), so I could probably do it in about half the time or less. It is probably a job that would not be that expensive to take to a mechanic, but my wife uses this car every day, so it was easier for me to do the repair in the evening.

I will see in the next couple of days if this has truly fixed the problem.

This is really helpful. I just got the code today after the engine jerked while driving on the highway. Did replacing it fix your issue?

Yes, Car was back to normal after I replaced the sensor.

This was super helpful in getting the job done. I did not have to remove the MAF since I was able to use a set of extensions to get down from the right side. To see what I was doing, I used an endoscope that I got for 25 bucks off amazon. It was a game changer for this job. Thanks for your help. I appreciate people like you who take the time to write up instructions after they have completed the job.

No worries, glad it helped. The endoscope is a great idea!