Youtube tips – shifter bushing and rounded bolts

Today I did an engine and transmission oil change on the 300SE. I don’t normally post basic maintenance to this website as it really isn’t that interesting. In this case, I used to tips I learned form MercedesSource videos that really sped up the job. MercedesSource are an online parts vendor, who also make some useful special tools. The owner, Kent, runs a youtube channel to promote the business. I’ve bought a couple of his special tools over the years and found them quite useful.

The first tip was for removing the bolt from the transmission oil pan. This bolt uses a hex fitting, which had been rounded off by a previous workshop. Last time I changed the transmission oil I made a huge mess as I had to remove the pan without first draining the oil. I obviously didn’t want to damage the bolt without a new one on hand.

This time I had the new bolt ready to go. The tip is to use a chisel to tap a divot into one side of the bolt and then tap against that divot in the direction to unscrew the bolt. This technique took all of a few seconds to remove the bolt. The new bolt was quite cheap. I don’t remember exactly how much as I purchased it a couple of years ago.

While bolting the transmission oil pan back on, I noticed that my lower shifter bushing was bad. It had largely disintegrated and the shift rod was no longer snug in the transmission gear selector. The 70s and 80s cars use a much better design than the 60s models in that there is a clip at the end of the rod that ensures it can’t fall out entirely. There might be a lot of slop in the lever, but it won’t leave you stranded. When the bushing failed on my 250SE, I had to use a bulldog clip to make a temporary fix to get the car back into the garage. Luckily I wasn’t stuck somewhere else.

I have previously done the shifter bushing on my 450SLC. There is quite a bit more room to work on the W126. MercedesSource sell a bushing press that makes installing the new bushings a doddle. It’s even easier if you use a little rubber grease. I only needed to do the lower one, the upper one seemed fine. These are the sort of parts that it makes sense to keep on hand if you own these cars. They are not expensive and it makes sense to check them each time you look under the car.

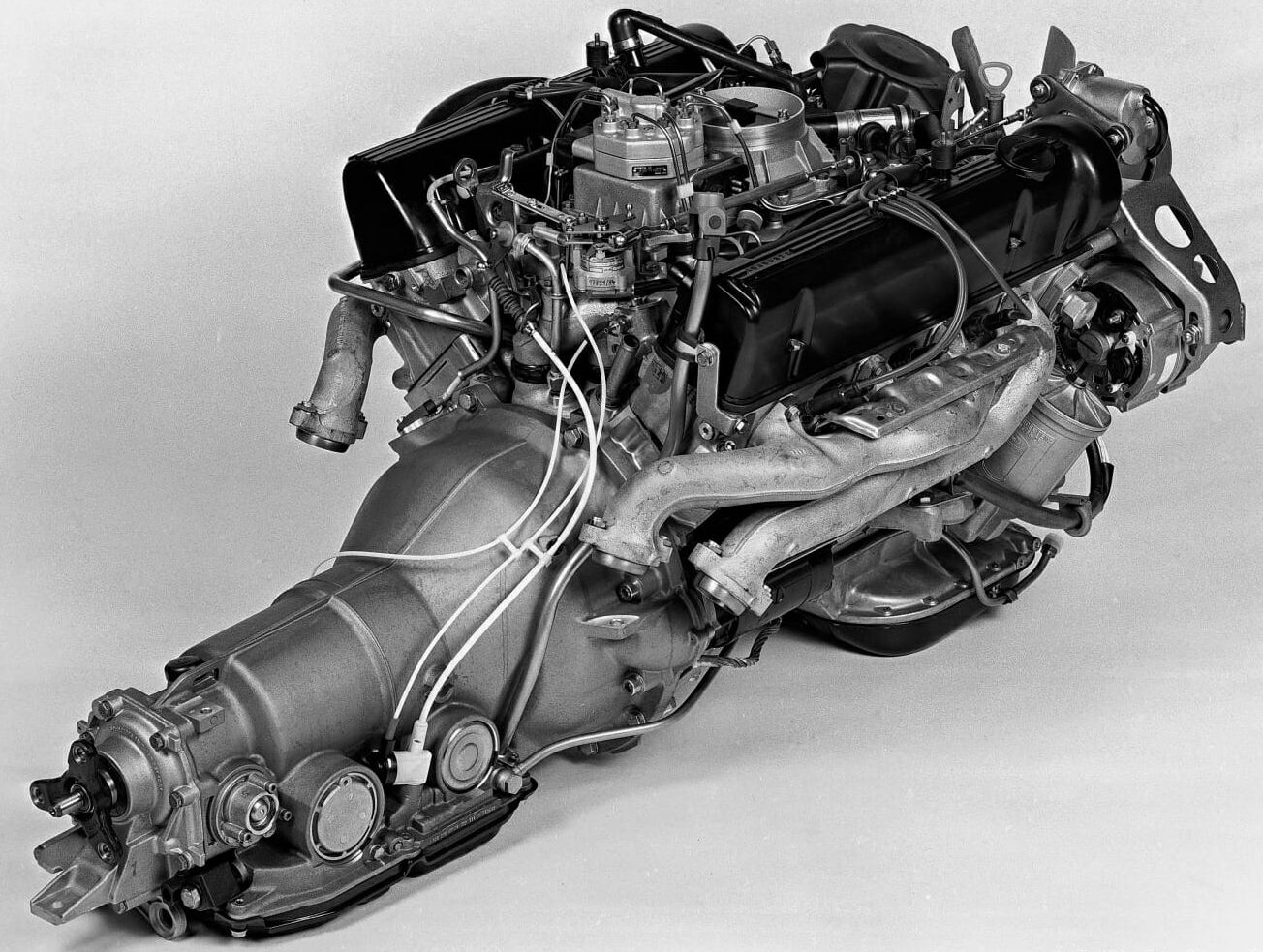

I had also planned to check the distributor cap, but I didn’t get time today. I’ve not checked it since I owned the car and its a part that is often neglected. The M103 is a bit of pain to get to compared to other motors. I also plan to check for vacuum leaks as the vacuum gauge on this car is at the halfway point at idle. It should be close to the left hand end. This probably means a vacuum leak.